Products Services

STYL’One Evo

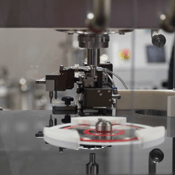

The STYL’One Evo is the most versatile single-punch tableting press for Research & Development, scale-up and production support. This allpurpose tableting instrument enables fast API characterization and single layer to multi-layer formulation development. Develop your formulation at full production speed with only a few grams of powder!

Fully instrumented, the STYL’One Evo is a real “tableting robot” to explore the design space (QbD) and analyze your formula with utmost efficiency. It is flexible with many modules and accessories to fit your needs. Several safety options are available depending on the potency of API you use.

Technical highlights:

- Force, displacement and radial measurements

- Force mode for cost-saving on API characterization

- Target thickness to mimic rotary tablet press

- Manual, advanced gravity and force feeding options

- Multi-layer up to five layers with three products

- Automatic core feeding system for tab-in-tab

- Replication of all types of rotary tablet presses

- Roll compaction mimicking for ultimate material sparing

- Can be upgraded to production standards (GMP) with external lubrication

Please get in touch with us and ask for your demo!

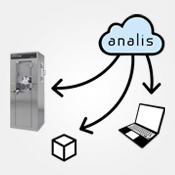

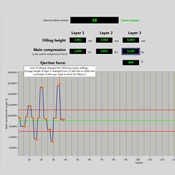

Analis Software

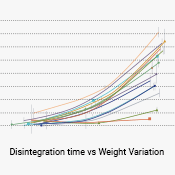

Analis, a MEDELPHARM development, is the most comprehensive data acquisition and analysis package suitable for every formulation scientists.

Standard R&D package drives the tablet press, acquires all the data and generates reports. Pre-defined compression profiles allows the user to mimic rotary production presses. Analis enables to control the STYL’One Evo in force or displacement mode to fulfil all your R&D needs.

Analis has been designed in different modules offering a wide range of solutions while keeping ease of use and ergonomics at the heart of the development.

- Multi-layer module and tab-in-tab

- Roll compaction module for dry granulation feasibility assessment

- GMP production module for clinical and commercial batch production

- Automatic data transfer from tablet testers

- Profil’One module to create tailor-made compression profiles

Base Analis R&D module can be installed on legacy single punch presses to share data.

R&D accessories

The STYL’One Evo benefits from a great number of options and accessories used in R&D environment.

- Innovative paddle force feeders

- Instrumented die for radial pressure

- Take-off force sensor

- Dual scale sensors

- Linear ejection system

- Good and bad tablet sorting chute

- Multi-layer module

- Tab-in-tab device

- Roll compaction mimicking for ultimate material sparing

- External lubrication system with micro-dispensing unit

- Safety (EOS or high containment)

Please get in touch with us to get more details!

GMP Production accessories

The STYL’One offers many accessories for the GMP Production environment.

- GMP software with CFR part 11 compliance

- Automatic weight regulation

- Good/bad tablet selection

- Linear ejection system

- External lubrication system with micro-dispensing unit

- Vacuum and negative pressure for operator safety

- FAT/SAT and IQ/OQ validation

- Advanced operator training

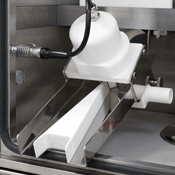

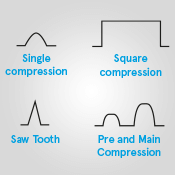

STYL’One Nano

The STYL’One Nano is the revolutionary benchtop R&D tablet press for demanding formulation scientists with price performance in mind. Characterize your API and develop your single layer formulation with only a few grams of powder!

Technical highlights:

- Benchtop model compact and mobile with a small footprint

- Driven by Alix, the most powerful integrated R&D software platform

- Force, displacement and radial measurements

- Bottom punch dynamics similar to the movements of a rotary press

- Designed with USP <1062> in mind (square, V-shape, pre- and main compression)

- Force mode for cost-saving on API characterization

- Target thickness to mimic small turret rotary tablet press

- Manual, advanced gravity and force feeding options

- Easy to handle – Easy to clean

An instrumented die or an external lubrication system can be added to your STYL’One Nano.

Please get in touch with us and ask for your demo!

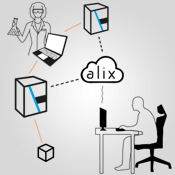

Alix Software Platform

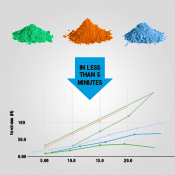

Alix is the new formulation development software platform conceived by MEDELPHARM for demanding formulation scientists in solid dosage form with future in mind. This intuitive and easy-to-use platform is a real time saver.

Alix software orchestrates the STYL’One Nano and all laboratory instruments connected to it.

Technical highlights:

- Drive all instruments from a single point

- Flexible interface to design and start experiment efficiently

- Multi-task capabilities: while running your experiment, upload tablet tester data and create your graphs

- Integrated analytics package: no need to export your data

- Pre-defined USP <1062> plots allowing tabletability assessment in a few minutes

- Time saving during your research projects

Currently running on the STYL’One Nano exclusively, Alix is designed to support other MEDELPHARM research presses in the future.

Please get in touch with us and ask for your demo!

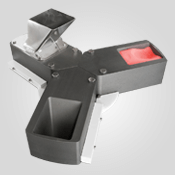

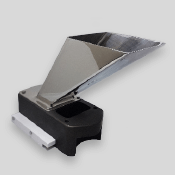

STYL’One MIST & Lubrication solutions

For many years MEDELPHARM engineers have focused on resolving sticking issues and minimizing ejection forces. Their successful research led to different developments to offer external lubrication, spraying lubricant where it’s needed and reducing its amount inside the formulation.

Two innovative solutions have been developed at MEDELPHARM:

- STYL’One Mist is a handy dosing spray, calibrated at 0,3 mg magnesium stearate/puff to be sprayed directly on the punch and die. It replaces comfortably the brush and vacuum procedure used in many labs. The Mist spray can be used on any single punch press!

-

MEDELPHARM lubrication pack is especially designed to deliver

small quantities of lubricant required by single punch presses. It consists of:

- A control system called “puff box” which dispenses a small dose of lubricant at given intervals on the punches and die.

- A compact and cost-effective micro-dispensing unit that delivers very small dose of lubricant.

Get in touch with us and let’s talk lubrication!

STYL’One Contained executions

Powders being more and more potent has made a higher level of protection essential to ensure operator safety.

The STYL’One series provides different operator safety executions which differ in specifications, technology and budget.

Standard

All STYL’One are easy to clean and produce tablets with minimal amount of active material in the compaction area.

The standard vacuum system keeps the compaction area clean and under slight negative pressure, limiting the exposure for the operator.

STYL’One Nano and STYL’One Evo can also be placed in a down flow booth for user protection.

The compaction area of the STYL’One Nano or Evo can also be flooded with Nitrogen allowing experiment with Oxygen-sensitive or explosive powder.

DryCon®

DryCon® execution has been designed to add an extra layer of safety by limiting operator exposure to airborne particles during operation.

This dry containment philosophy includes negative pressure generation and monitoring, glove ports, safe entry and exit of material and tablet collection.

SMEPAC testing by a certified third-party confirmed a high level of protection.

The STYL’One Evo DryCon® can also be safely operated with the glove ports open when manipulating non-hazardous material.

WipCon®

When using Highly-Potent API, a full OEB 5 containment solution with isolator can be deployed for both R&D and GMP applications.

The negative pressure control and monitoring combined with air filtration and safe cleaning reduces drastically the operator exposure.

The tablet press can safely run while the operator performs other tasks inside the contained chamber like weighing, hardness measurements or cleaning.

SMEPAC testing by a certified third-party confirmed a high level of protection.

The STYL’One Nano & Evo WipCon® can also be safely operated with the isolator open when manipulating non-hazardous material.

Please get in touch with us and let’s talk containment!